Many techniques have been developed to manipulate the different properties of the cellular microenviroment. Recently, the advent of light-induced biochemical compounds has allowed scientists to define the biochemical and structural features of cellular matrices by photo micropatterning and photolithography. Scientists can precisely define the spatial distribution of UV light to create unique cellular microenvironments without any use of masks or physical contact with the substrate.

Light-Modulated Protein-Protein Interactions on a Coverslip Surface

This video shows a protein-protein interaction that is inhibited by blue light exposure. One component is coupled to the coverslip through biotin surface chemistry, the other is labeled with mCherry, and binds to the coverslip in the dark. Patterned illumination with the Polygon results in revesible dissociation of the mCherry-tagged protein, which rebinds within minutes of turning off blue light exposure. The Wittmann lab is working on developing this into a cell adhesion surface that can be controlled by light (Courtesy Dr Torsten Wittmann, University California San Francisco, USA).

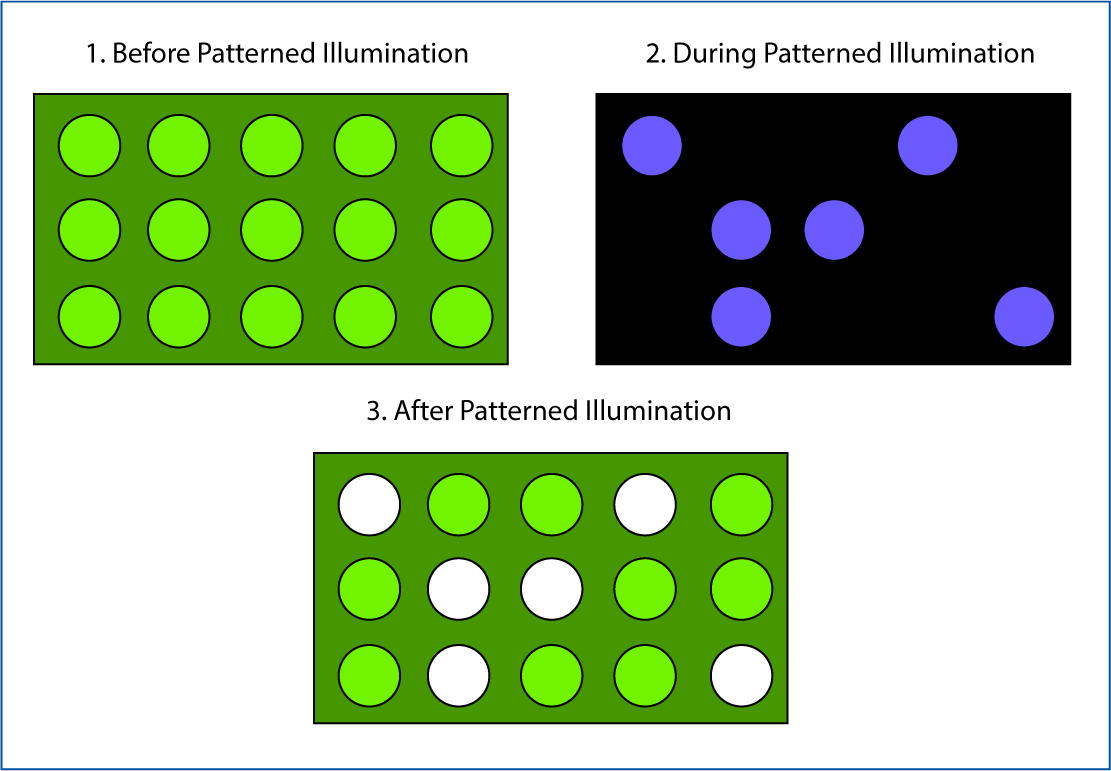

Spatiotemporal Control Over Membrane Degradation in a Multi-Well Array

van der Vlies. 2019 explored how to effective grow and retrieve cells from individual wells in a microwell bacterial array. The authors developed a light-sensitive hydrogel to restrict bacterial cells movement and used the Mightex’s Polygon to illuminate individual well with UV light (365nm) to release and retrieve bacterial cells.

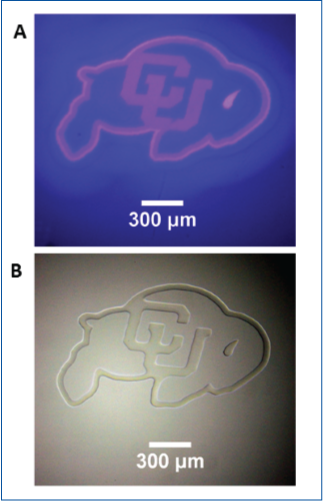

Photopatterning of an Acrylate Film

A 50 um film of liquid tetra (ethylen glycol) diacrylate, containg 1 wt% Irgacure 819 photointiator was irradiated through a glass coverslip, using the Polygon and a 400nm LED light source to project a pattern onto the film surface. (A) Projection of CU logo image using the 400nm LED and a 4X objective. (B) Brightfield image of the resulting pattern in the film. Photopolymerization causes a large change in refractive index in the resin, allowing immediate visualization of the pattern. Standard development techniques could subsequently be performed by washing the film in solvent to remove the unexposed areas of liquid resin (Courtesy Gayla Berg, University of Colorado, USA).

Photopatterning

with Mightex’s Polygon

Contact Us About Polygon

"*" indicates required fields